Research continues at a steady pace into building longer-lasting, less expensive rechargeable batteries for everything from watches, to mobile phones, even to electric cars.

Canadian research has just made a big step in that direction thanks to the Nazar Lab in Ontario at the University of Waterloo, one of the largest electrochemistry materials labs in Canada.

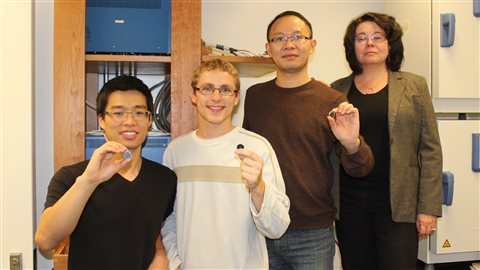

Professor Linda Nazar, professor of chemistry, and senior Canada research chair in solid-state energy materials, who has developed new understanding in connection with lithium-sulphur technology.

ListenAs rechargeable batteries are used, the materials change slightly. Recharging them, changes that new material back into the original in order to produce electricity once again.

However, the material can never be fully recovered back to its original state, and each recharging cycle results in slightly less capacity, until the battery can no longer be recharged.

The trick for battery makers is to reduce the amount of original material changed each time, or in other words, increase the ability to re-convert the material back to its original form.

This means the battery can be recharged more often for a longer life.

The Nazar group has developed an electrode composite material that enables lithium-sulfur cells to work more efficiently. Sulfur is a light, abundant, and much cheaper cathode material, compared to the lithium-metal oxides used in current lithium-ion batteries

Sulphur works well but exhausts itself quickly. The research breatkthrough came when the group experimented with manganese dioxide nanosheets that captured the “converted sulphur” (polysulphide) so that it could be reconverted back to the original sulphur without dissolving extensively in the electrolyte. The capture process relies on chemical bonds formed with species on the nanosheet surface.

It is so efficient that prototype experimental efforts have shown one of their small batteries can be recharged (“cycled”) up to 2,000 times.

Professor Nazar says the understanding they have developed of the process and materials can open the door to a wide variety of other developments, even as research continues towards creating more efficient rechargeable batteries.

Others involved in the research team include postdoctoral fellow Xiao Liang, and grad students Connor Hart and Quan Pang along with Drs.Thomas Weiss and Arnd Garsuch at BASF. The BASF International Scientific Network for Electrochemistry and Batteries funded the research, and NSERC (Canada) provided the underlying funding to support the Nazar Electrochemistry Materials Lab.

For reasons beyond our control, and for an undetermined period of time, our comment section is now closed. However, our social networks remain open to your contributions.