It’s been an extremely ambitious project, and an expensive one, but it’s nearing completion, and the excitement and world interest is running high.

Pollution from coal-fired electrical generating stations has long been major concern for the environment. In the prairie province of Saskatchewan, they are hoping to become world leaders in changing that.

For SaskPower president and CEO Robert Watson, it will be the culmination of years of planning and building.

Listen

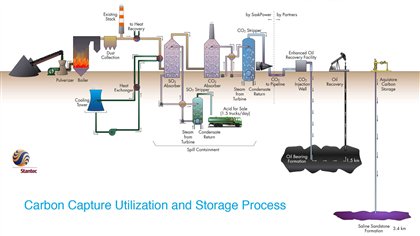

Near Estevan, Saskatchewan, is SaskPower’s largest generating facility. It was built to take advantage of vast amounts of nearby and easily mined coal. For several years this Boundary Dam Power plant has been the site of an ambitious project to capture, convert, reuse and recycle the majority of smokestack emissions from one of its units.

The average CO2 output from a coal-powered generating unit is 1100 tonnes per Gigawatt hour. New Canadian regulations coming into effect in 2015 state that when a unit reaches 50 years of age, its emmissions must be reduced to less than half that figure at 420t/gw hour, or the unit must be shut down.

The objective for Unit 3 at Boundary Dam Power Station, with the recovery and recycling, is projected to be far less at 140t/gw hour. All the rest of the CO2(about 90% of total), along with a majority of sulphur dioxide, nitrous oxide and fly ash, will be recovered.

To accomplish this, and in conjunction with the rebuilding of Unit 3, another large facility is being built called the “capture island”.

When it all comes on line, it will be the world’s first commercial-scale, post-combustion, carbon-capture power project. The purpose is not only to be a world leader in being green from what is generally a highly polluting process, but to also sell the collected and converted former pollutants and generate profits.

Some of the C02 will be sold to the oil industry, some will be stored deep underground, sulphur will be converted to sulphuric acid and sold on the market, and fly ash (soot) will be collected and sold to cement companies where it’s used to improve quality of cement products.

In addition, another test facility is being built as a beta site for other companies to test innovative equipment and technologies towards reducing emmissions from coal plants.

In creating these many new processes and technologies, including operating procedures, SaskPower has received several international patents. It is also generating a great deal of interest from other power generating operations around the world as the process nears completion prior to coming on line with the Unit 3 power island in September, and the capture island commissioned in October, and the integrated process under way early in 2014.

For reasons beyond our control, and for an undetermined period of time, our comment section is now closed. However, our social networks remain open to your contributions.