A report into a derailment and fire of a train of crude oil tankers earlier this month says the new standard of rail cars has still proven inadequate to prevent bursting and fires.

Following the deadly Lac Megantic Qc oil train disaster, the Transportation Safety Board (TSB) recommended higher, and stronger standards for oil and chemical transport. The industry standard for such tanker cars was a design known as DOT-111. The new standard the industry agreed to was a design called CPC-1232.

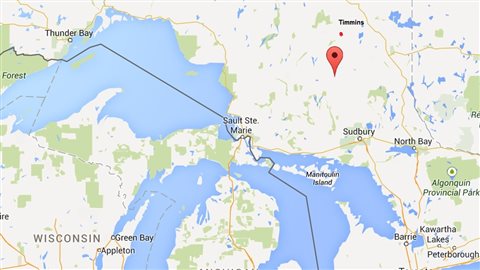

The 100 car train was travelling slightly slower than the 64km/h speed restriction in -31C temperatures in the remote area when 29 tankers of the new design derailed. Several burst and the spilled oil caught fire.

Another fire this past Sunday in West Virginia in the US, also involved tankers of the new CPC- 1232 standard.

The CPC-1232 tankers are made of thicker steel than the old tankers, with improved valve and protective technology on the top and bottom and a half –height “head shield” on the front and back of the car to protect the tank from being punctured by a rock or branch.

The TSB report quotes Chief Operating Officer Jean L Laporte, “The TSB has been calling for tougher standards for Class 111 tank cars for several years. Here is yet another example of tank cars being breached, and we once again urge Transport Canada to expedite the introduction of enhanced protection standards to reduce the risk of product loss when these cars are involved in accidents.”

The report also says that “the preliminary assessment of the CPC-1232-compliant tank cars involved in this occurrence demonstrates the inadequacy of this standard given the tank cars’ similar performance to the legacy Class 111 tanks cars involved in the Lac-Mégantic accident.”

The estimated cost to retrofit a legacy 111 tanker to the CPC-1232 standard is $20,00-30,000

However some experts say that it would be virtually impossible to make a tanker that could withstand an impact at over 100km/h, the speed the tankers were travelling in the Lac Megantic disaster.

The investigation is continuing with the TSB examining several aspects of the derailment in which no-one was injured and due to the remote location, no evacuations were needed.

The next steps in the TSB investigation of the Gogama derailment include the following:

Examination of rail components and suspect wheel recovered from the derailment site

- Sampling and testing of product from select cars

- Review of Wheel Impact Load Detector records for subject train and 2 previous trains

- Review of all track infrastructure maintenance records for the area

- Review of CN Engineering Track Standards and cold weather policy

- Review of TC-approved Track Safety Rules

- Review and evaluation of ERAP and emergency response

- Conducting additional interviews as required.

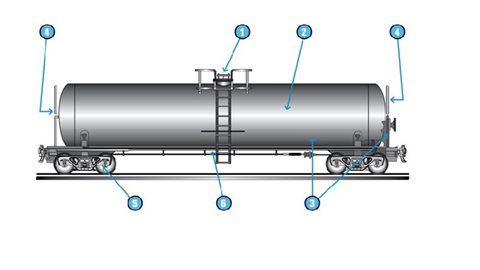

NEW STANDARD PROPOSED TC-140 (see diagramme below)

- Top-Fitting Protection – This feature essentially covers the valves and accessories on top of a tank car. It also protects the pressure release valve from damage. For the TC-140 tank car, the top-fitting requirements would be similar to the current requirements for tank cars transporting dangerous goods that are Toxic by Inhalation.

- Thermal Protection including a Jacket – This feature is an outer cover that is placed on the exterior of the shell, used mainly to provide thermal protection and keep insulation in place. The thermal protection required for the TC-140 tank car would have to withstand a 100 minute pool fire and a 30 minute jet fire without rupturing.

- Thicker Normalized Steel – Thicker shell and heads provide improved puncture resistance and structural strength. Using normalized steel improves the toughness and ductility of the material, providing increased fracture resistance of the tank car.

- Head Shields – This feature helps protect the head of the tank car from puncture. The improved TC-140 proposes a full head shield that covers the entire head of the tank car vs the current half-height shield of the latest CP-C1232 standard

- Electronically Controlled Pneumatic Brakes – This feature significantly reduces train forces during emergency braking, reducing the likelihood of potential derailments and providing better and smoother braking abilities during train operation.

- Improved Bottom Outlet Valves – This feature is designed for valves to withstand derailments and helps to ensure they don’t leak during a potential accident.

For reasons beyond our control, and for an undetermined period of time, our comment section is now closed. However, our social networks remain open to your contributions.